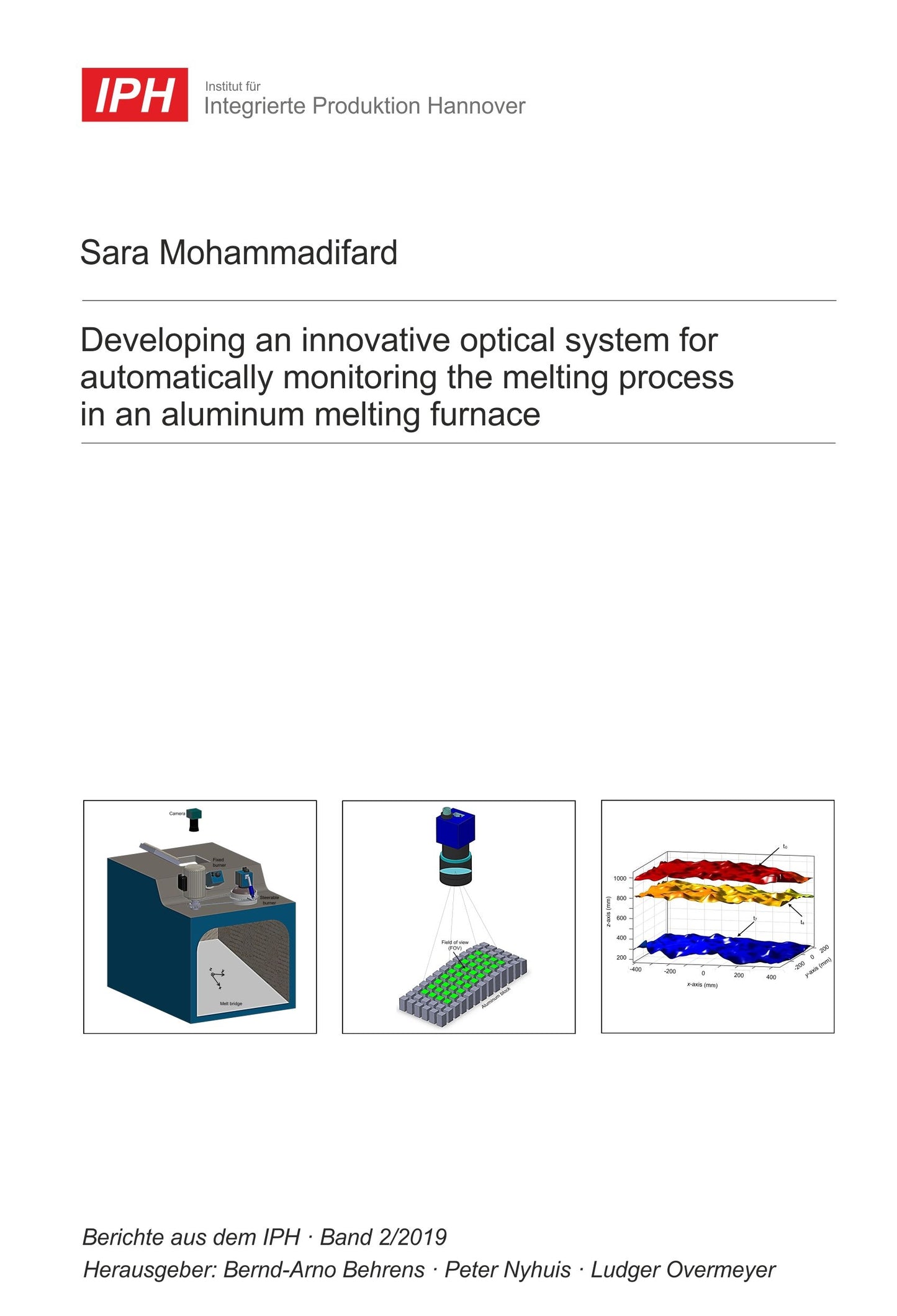

Developing an innovative optical system for automatically monitoring the melting process in an aluminum melting furnace

Autor: Sara Mohammadifard

ISBN: 978-3-95900-396-4

Dissertation, Leibniz Universität Hannover, 2019

Herausgeber der Reihe: Bernd-Arno Behrens, Peter Nyhuis, Ludger Overmeyer

Band-Nr.: IPH 02/2019

Umfang: 122 Seiten, 56 Abbildungen

Schlagworte: Schmelzprozess, Analysealgorithmus, Lichtfeldkamera, Prozessüberwachung, Melting process, Analysis algorithm, Light-field camera, Process monitoring

Kurzfassung: Ever-stricter requirements for the quality of the finished product and the energy consumption pose difficult challenges for industry, especially the automotive industry. The market demands high-quality components at a reasonable cost. Modern technologies and innovative methods help to meet this challenge. Process monitoring has become a key technology and enables the improvement of safety, quality, and efficiency in various fields. Until recently, production ̶ from the design of the aluminum melting furnace to the daily process ̶ relied largely on tra-ditional methods and experience. This thesis investigates a new method for monitoring a melt-ing process and shape changes in the furnace by means of optical sensors for the first time. To this end, this thesis deals with an innovative analysis algorithm for using an optical meas-uring system that is able to monitor the melting block despite the red-hot furnace walls.